Insulation plays a critical role in modern building design by improving energy efficiency, fire safety, and acoustic comfort. Among the most commonly used insulation materials are glass wool and rock wool. Although both belong to the mineral wool category, they differ significantly in raw materials, performance characteristics, applications, and cost. Understanding these differences helps architects, engineers, contractors, and buyers select the most suitable solution for specific project requirements.

1. What Are Glass Wool and Rock Wool?

Glass Wool

Glass wool is manufactured by melting recycled glass, sand, and other raw materials at temperatures of approximately 1,400°C, then spinning the molten material into fine fibers. The result is a lightweight, flexible insulation material with excellent thermal and acoustic performance, commonly used in residential and commercial buildings.

Rock Wool

Rock wool, also known as stone wool, is produced by melting natural volcanic rock such as basalt at higher temperatures, typically 1,450–1,600°C. The molten rock is spun into dense fibers and formed into boards or mats. Due to its structure, rock wool offers high mechanical strength and superior fire resistance.

2. Key Differences in Physical Properties

Raw Materials & Density

-

Glass Wool: Made primarily from recycled glass, with a typical density of 10–100 kg/m³

-

Rock Wool: Made from basalt and similar rocks, with a higher density of 40–200 kg/m³

The higher density of rock wool contributes to improved structural stability and sound insulation, while glass wool’s lower density allows for easier handling and installation.

3. Thermal Insulation Performance

Both materials provide effective thermal insulation, with slight differences:

-

Glass Wool: Thermal conductivity typically ranges from 0.030–0.048 W/m·K, making it highly efficient for walls, roofs, and floors.

-

Rock Wool: Thermal conductivity is generally around 0.038–0.042 W/m·K, offering stable insulation performance, especially in dense applications.

4. Fire Performance & Temperature Resistance

Fire resistance is one of the most important distinctions:

-

Glass Wool: Non-combustible, with maximum service temperatures around 260–270°C

-

Rock Wool: Non-combustible and capable of withstanding temperatures of 600°C or higher, in some cases exceeding 1000°C

As a result, rock wool is widely used in fire-rated systems, industrial insulation, and high-temperature environments.

5. Acoustic Performance

Sound performance depends largely on material density:

-

Glass Wool: Fine fibers and a porous structure provide excellent sound absorption, particularly for airborne noise in residential and commercial interiors.

-

Rock Wool: Higher density improves sound insulation, especially for low-frequency and industrial noise control.

6. Moisture Resistance & Sustainability

Moisture Behavior

-

Glass Wool: Typically requires vapor barriers or facings in humid environments.

-

Rock Wool: Naturally more moisture-resistant due to its dense fiber structure.

Environmental Impact

-

Glass Wool: Commonly contains 20–30% recycled content

-

Rock Wool: May contain 70% or more recycled material, depending on production methods

Both materials are recyclable at end of life and do not contain asbestos.

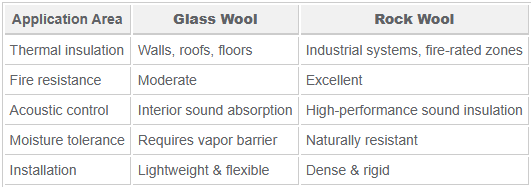

7. Typical Applications

8. Cost Considerations

Glass wool is generally more cost-effective, making it suitable for large-scale or budget-sensitive projects. Rock wool typically has a higher material cost, which is justified in applications requiring enhanced fire resistance, durability, and acoustic performance.

Conclusion: Choosing the Right Insulation Material

-

Choose glass wool for lightweight, flexible, and cost-efficient insulation in standard building applications.

-

Choose rock wool where fire resistance, mechanical strength, and long-term durability are critical.

For project-specific recommendations, explore Kalax Insulation Products or contact our technical team for professional support.

FAQ

Q: Is rock wool better than glass wool?

A: It depends on the application. Rock wool excels in fire resistance and durability, while glass wool offers better flexibility and cost efficiency.

Q: Can glass wool and rock wool be used in the same building?

A: Yes. Many projects combine glass wool for general insulation and rock wool for fire-critical or industrial areas.

Q: Are glass wool and rock wool safe?

A: Both are non-combustible mineral wool materials that meet international safety standards. Proper protective handling is recommended during installation.